Table of Contents

- Introduction to Vertical Drying Range Machines 1.1 Overview

1.2 Importance in Textile Industry

1.3 Historical Evolution - Design and Components 2.1 Basic Structure

2.2 Key Components

2.3 Working Mechanism - Types of Vertical Drying Range Machines 3.1 Conventional Vertical Drying Machines

3.2 Modern Vertical Drying Machines

3.3 Comparison with Horizontal Dryers - Technical Specifications 4.1 Size and Capacity

4.2 Energy Consumption

4.3 Control Systems - Operation and Maintenance 5.1 Installation

5.2 Operation Procedures

5.3 Regular Maintenance

5.4 Troubleshooting Common Issues - Advantages and Disadvantages 6.1 Advantages

6.2 Disadvantages - Applications in the Textile Industry 7.1 Fabric Types Suitable for Vertical Drying

7.2 Industry Segments Benefiting from VDR - Innovations and Future Trends 8.1 Technological Advancements

8.2 Sustainable Practices

8.3 Future Outlook - Case Studies 9.1 Successful Implementations

9.2 Lessons Learned - Conclusion

Chapter 1: Introduction to Vertical Drying Range Machines

1.1 Overview

Vertical Drying Range (VDR) machine textile industry mein ek important role play karta hai. Ye machines specially designed hoti hain to dry fabrics in a vertical orientation. Fabrics ko vertically hang karke, ye machines drying process ko efficient aur effective banati hain. Vertical drying method se fabrics evenly dry hoti hain aur unki quality bhi maintain hoti hai.

1.2 Importance in Textile Industry

Textile industry mein drying process critical hai, kyunki proper drying se fabric ki strength, color fastness, aur appearance ensure hota hai. VDR machines ka use karke, manufacturers high-quality fabrics produce karte hain jo market standards ko meet karti hain. Ye machines not only drying process ko speed up karti hain, but also energy-efficient hoti hain, jo cost-saving aur environmental friendly bhi hoti hain.

1.3 Historical Evolution

Vertical Drying Range machines ka evolution textile machinery development ka ek significant part hai. Initially, traditional horizontal drying methods use hoti thi, jo time-consuming aur less efficient thi. Lekin, jaise-jaise technology advanced hui, vertical drying methods introduce hui, jo textile drying process mein ek revolutionary change le aayi. VDR machines ka design continuously improve ho raha hai, aur aaj ke modern VDR machines highly automated aur user-friendly hain.

Chapter 2: Design and Components

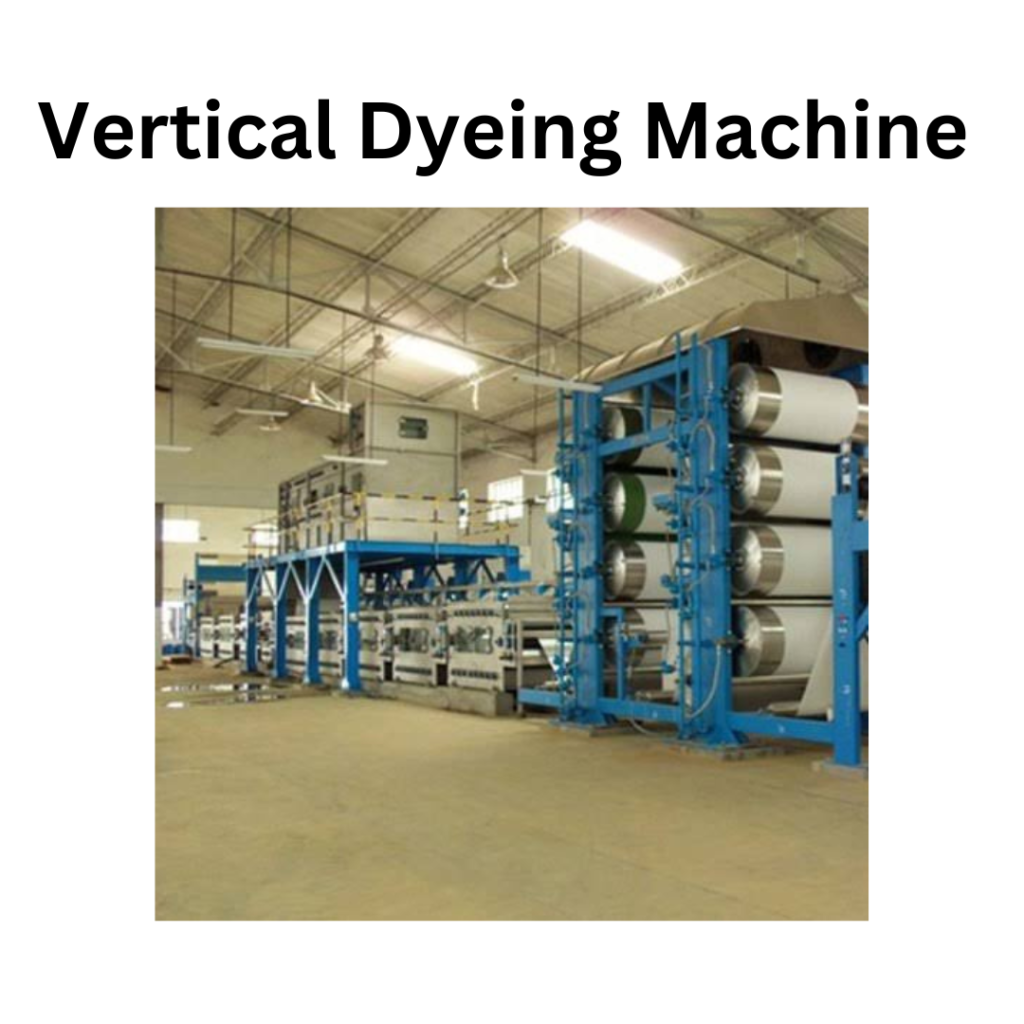

2.1 Basic Structure

VDR machines ka basic structure vertically oriented hota hai, jahan fabrics ko hang karke dry kiya jata hai. Machine ka frame robust materials se bana hota hai jo long-lasting aur durable hota hai. Machine ka design aisa hota hai ki it can handle different types of fabrics without damaging them.

2.2 Key Components

VDR machines ke key components mein include hoti hain:

- Drying Chambers: Jahan fabrics ko dry kiya jata hai.

- Heating Elements: Jo required temperature provide karti hain.

- Fans and Blowers: Jo air circulation ensure karti hain for uniform drying.

- Conveyor Belts: Jo fabrics ko move karti hain throughout the drying process.

- Control Panel: Jo machine ke operations ko monitor aur control karta hai.

2.3 Working Mechanism

VDR machines ka working mechanism simple yet efficient hota hai. Fabrics ko machine ke entry point pe load kiya jata hai, aur conveyor belts ke through vertically hang kiya jata hai. Heating elements se generated heat aur fans ke through circulated hot air fabrics ko dry karti hain. Control panel se temperature aur drying time set kiya jata hai, ensuring consistent and high-quality drying.

Chapter 3: Types of Vertical Drying Range Machines

3.1 Conventional Vertical Drying Machines

Conventional VDR machines basic design aur manual operations pe depend karti hain. Ye machines low-cost hoti hain, lekin efficiency aur automation mein modern machines se piche hain. Manual control aur monitoring required hota hai, jo labor-intensive hota hai.

3.2 Modern Vertical Drying Machines

Modern VDR machines highly advanced aur automated hoti hain. Inmein various sensors aur control systems integrated hote hain jo precise temperature aur drying time maintain karte hain. Automation se not only drying process fast hota hai, but also energy consumption reduce hoti hai. Modern machines ka design more fabric-friendly hota hai, jo delicate fabrics ko bhi without damage dry kar sakti hain.

3.3 Comparison with Horizontal Dryers

Horizontal dryers aur VDR machines ke beech main major differences hain. Horizontal dryers mein fabrics ko flat lay karna padta hai, jo uneven drying cause kar sakta hai. VDR machines mein fabrics ko hang karne se, gravity-assisted drying hota hai jo more uniform aur efficient hai. Horizontal dryers space-consuming hoti hain, while VDR machines vertical design ki wajah se space-efficient hoti hain.

Chapter 4: Technical Specifications

4.1 Size and Capacity

VDR machines different sizes aur capacities mein available hoti hain, depending on the requirement of the textile plant. Small-scale units ke liye compact models available hain, while large-scale operations ke liye high-capacity machines design ki gayi hain. Capacity ka selection based on production volume aur fabric type hota hai.

4.2 Energy Consumption

Energy consumption VDR machines ka ek important factor hai. Modern VDR machines energy-efficient designs aur advanced heating elements use karti hain jo minimal energy consume karte hain. Proper insulation aur optimized air circulation se energy wastage prevent hota hai, making these machines cost-effective.

4.3 Control Systems

Control systems VDR machines ka ek critical component hain. Modern control panels with digital displays aur programmable logic controllers (PLCs) machines ko easy-to-operate banate hain. Operators ko precise temperature, drying time, aur fabric tension control karne ki facility milti hai, ensuring consistent output quality.

Chapter 5: Operation and Maintenance

5.1 Installation

VDR machines ka installation process detailed aur systematic hota hai. Proper foundation aur alignment ensure karna critical hai for smooth operation. Installation guide follow karke aur professional technicians se assistance lekar installation process complete kiya jata hai.

5.2 Operation Procedures

Operation procedures clearly defined hoti hain to ensure safe and efficient machine running. Operators ko machine start-up, fabric loading, drying process monitoring, aur shutdown procedures properly follow karna chahiye. Safety protocols aur emergency procedures ka bhi strict adherence zaroori hai.

5.3 Regular Maintenance

Regular maintenance se VDR machines ki longevity aur performance ensure hoti hai. Scheduled inspections, cleaning of components, lubrication of moving parts, aur timely replacement of worn-out parts maintenance routine ka part hain. Proper record keeping aur maintenance logs se machine history track kiya jata hai.

5.4 Troubleshooting Common Issues

Common issues like uneven drying, temperature fluctuations, aur mechanical failures troubleshooting techniques se resolve kiya jata hai. Operators aur maintenance staff ko basic troubleshooting skills aur knowledge hona chahiye to quickly address issues without significant downtime.

Chapter 6: Advantages and Disadvantages

6.1 Advantages

- Uniform Drying: Vertical orientation se fabrics evenly dry hoti hain.

- Space Efficiency: Vertical design se plant floor space efficiently utilize hota hai.

- Energy Efficiency: Advanced heating elements aur insulation se energy consumption kam hota hai.

- Automation: Modern control systems se operation easy aur consistent hota hai.

6.2 Disadvantages

- Initial Cost: High initial investment required for modern VDR machines.

- Maintenance Requirement: Regular maintenance aur skilled technicians ki zaroorat hoti hai.

- Limited Fabric Types: Not suitable for all types of fabrics, especially very heavy ones.

Chapter 7: Applications in the Textile Industry

7.1 Fabric Types Suitable for Vertical Drying

VDR machines different types of fabrics dry karne ke liye suitable hain, including:

- Cotton: Uniform drying aur color retention.

- Silk: Gentle drying without damage.

- Synthetic Fabrics: Quick drying and shape retention.

- Blended Fabrics: Even drying aur fabric integrity maintain karna.

7.2 Industry Segments Benefiting from VDR

Textile industry ke various segments VDR machines se benefit hoti hain, including:

- Apparel Manufacturing: High-quality garment production.

- Home Textiles: Bed sheets, curtains, and upholstery fabrics.

- Technical Textiles: Industrial fabrics requiring precise drying conditions.

- Textile Dyeing and Printing: Consistent color application aur fast drying.

Chapter 8: Innovations and Future Trends

8.1 Technological Advancements

Technological advancements continuously VDR machines ko improve kar rahe hain. Advanced sensors, IoT integration, aur AI-based control systems machines ko smarter aur more efficient bana rahe hain. In innovations se not only drying process fast hota hai, but also energy efficiency improve hoti hai.

8.2 Sustainable Practices

Sustainability textile industry ka ek major focus hai, aur VDR machines ismein significant role play kar sakti hain. Energy-efficient designs, renewable energy sources ka use, aur eco-friendly materials se machines manufacture karna sustainable practices ko promote karta hai. Water recycling aur waste heat recovery systems integrate karne se environmental impact kam hota hai.

8.3 Future Outlook

Future mein VDR machines ka role aur bhi significant hone wala hai. Industry 4.0 aur smart manufacturing trends se machines more connected aur intelligent hoti ja rahi hain. Predictive maintenance aur remote monitoring se downtime reduce hoga aur productivity enhance hogi. Sustainable practices ko integrate karke, future VDR machines not only efficient but also environmentally friendly hongi.

Chapter 9: Case Studies

9.1 Successful Implementations

Case studies of successful VDR machine implementations textile industry mein in machines ki effectiveness aur benefits ko highlight karti hain. Different textile plants ne VDR machines install karke, production efficiency aur fabric quality mein significant improvement dekha hai. Case studies detailed analysis aur data provide karti hain jo industry professionals ke liye valuable insights hain.

9.2 Lessons Learned

Case studies se valuable lessons bhi learn kiya ja sakta hai. Installation challenges, operational issues, aur maintenance practices ke through plants ne jo experience gain kiya hai, wo industry ke liye guiding light ho sakta hai. These lessons future implementations ko smooth aur successful banane mein help kar sakti hain.

Chapter 10: Objects and Purposes of Vertical Drying Range Machines

Vertical Drying Range (VDR) machines ke objects aur purposes textile manufacturing process ko optimize karna aur high-quality fabrics ensure karna hain. In machines ke use se drying process fast, efficient, aur uniform hota hai, jo overall production cycle ko improve karta hai.

- Efficient Drying: Vertical drying method se fabrics ko evenly aur quickly dry kiya jata hai.

- Quality Maintenance: Fabrics ki quality maintain karna, including color fastness aur texture integrity.

- Energy Efficiency: Optimized energy use se cost reduction aur environmental impact minimize karna.

- Automation and Control: Advanced control systems se consistent results aur minimal manual intervention ensure karna.

- Space Utilization: Vertical design se plant floor space efficiently utilize karna.

Chapter 11: Understanding and The Importance of Vertical Drying Range Machines

Vertical Drying Range machines ko samajhna aur unki importance recognize karna textile industry ke professionals ke liye critical hai. Ye machines not only production efficiency ko enhance karti hain, but also fabric quality ko maintain karti hain, jo market competitiveness ke liye essential hai.

- Efficiency and Productivity: High-speed drying se production rate increase hota hai.

- Consistent Quality: Precise temperature aur humidity control se uniform fabric quality ensure hoti hai.

- Cost-Effectiveness: Energy-efficient operation se production costs reduce hoti hain.

- Sustainability: Environment-friendly practices se sustainability goals achieve hoti hain.

Chapter 12: Common Problems Occurring During Operation

Vertical Drying Range machines ke operation ke dauran kuch common problems occur hoti hain jo production ko affect kar sakti hain.

- Uneven Drying: Fabrics unevenly dry hoti hain due to improper air circulation.

- Temperature Fluctuations: Inconsistent temperature control se fabric quality affect hoti hai.

- Mechanical Failures: Moving parts ka wear and tear machine breakdown cause kar sakta hai.

- Energy Wastage: Poor insulation aur inefficient heating elements se energy wastage hoti hai.

- Control System Issues: Faulty sensors aur control systems se inaccurate drying parameters set hoti hain.

Chapter 13: Common Defects in Fabrics

Vertical Drying Range machines ke use ke baad kuch common fabric defects occur ho sakte hain. In defects ko identify karna aur unhe minimize karna important hai to ensure high-quality output.

13.1 Minimum 5 Common Defects

- Wrinkles: Improper fabric tension aur uneven drying se wrinkles form ho sakti hain.

- Color Variation: Inconsistent temperature aur humidity control se color variation ho sakta hai.

- Shrinkage: Excessive heat exposure se fabrics shrink ho sakte hain.

- Surface Damage: Over-drying aur high tension se fabric surface damage ho sakti hai.

- Streaks and Spots: Uneven drying se streaks aur spots form ho sakte hain on the fabric surface.

Chapter 14: Conclusion

14.1 Conclusion in One Line

Vertical Drying Range machines textile industry mein drying process ko revolutionize kar rahi hain, ensuring efficiency, quality, and sustainability.

Chapter 15: Frequently Asked Questions

15.1 Minimum 10 Questions and Answers

- Q1: Vertical Drying Range machines kya hoti hain? A1: Vertical Drying Range machines fabric drying ke liye used hoti hain, jahan fabrics vertically hang karke dry kiya jata hai.

- Q2: VDR machines ka main benefit kya hai? A2: VDR machines uniform drying, energy efficiency, aur high-quality fabric ensure karti hain.

- Q3: Vertical Drying Range machines mein kaun se fabrics dry kiye ja sakte hain? A3: Cotton, silk, synthetic, aur blended fabrics VDR machines mein dry kiye ja sakte hain.

- Q4: Vertical Drying Range machines ka installation kaise hota hai? A4: Installation professional technicians ke through kiya jata hai, jo proper alignment aur foundation ensure karte hain.

- Q5: VDR machines ke control systems kaise operate hote hain? A5: Modern VDR machines advanced control panels aur PLCs se operate hoti hain, jo precise temperature aur drying time set karne ki facility deti hain.

- Q6: VDR machines ki regular maintenance kyun zaroori hai? A6: Regular maintenance se machines ki longevity aur performance ensure hoti hai, aur downtime reduce hota hai.

- Q7: Vertical Drying Range machines energy-efficient kaise hoti hain? A7: Advanced heating elements aur proper insulation VDR machines ko energy-efficient banate hain.

- Q8: VDR machines ka historical evolution kya hai? A8: Initially traditional horizontal dryers use hoti thi, jo inefficient thi. VDR machines ka development textile drying process ko revolutionize kiya hai.

- Q9: Vertical Drying Range machines ke common issues kaise troubleshoot kiye ja sakte hain? A9: Uneven drying, temperature fluctuations, aur mechanical failures jaise common issues troubleshooting techniques se resolve kiye ja sakte hain.

- Q10: Future mein VDR machines ka role kya hoga? A10: Future mein VDR machines ka role aur bhi significant hoga, with technological advancements aur sustainable practices ke integration ke sath.

Thank you for giving your valuable time: Pruthvi Pandya