Introduction to Grey Fabric Inspection:

Grey inspection is a crucial stage in textile processing, serving as the first line of defense against defects and ensuring the quality of the final product. Grey fabric, referring to unfinished fabric straight from the loom, undergoes thorough inspection to identify any flaws or irregularities before further processing.

Objects and Purposes of Grey Inspection:

The primary objectives of grey fabric inspection are to maintain quality standards, identify defects, and ensure consistency throughout the production process. By Manufacturers may maintain their reputation in the market, satisfy customers, and save manufacturing expenses by following strict inspection protocols. Grey inspection is used for more than just finding flaws; it’s a quality control tool that helps producers produce textiles that either meet or surpass industry standards.

What inspect in Grey inspection?

• Check every broken and loose yarn in fabric.

• Check and count every knots in fabric.

• Check and count every stain in fabric.

• Measure fabric width.

• Measure fabric length with help of meter counting machine.

• Count the reeds and peaks in a 1 cm square of fabric.

Grey Inspection Process:

The grey fabric inspection process comprises several key stages to comprehensively assess the fabric’s quality and integrity. Upon receiving the grey fabric rolls, inspectors meticulously examine each roll for any visible defects such as stains, holes, or weaving irregularities. Subsequently, the fabric undergoes physical testing to evaluate parameters such as tensile strength, dimensional stability, and colorfastness. Throughout the inspection process, detailed documentation is maintained to record inspection results, enabling traceability and accountability.

Four Point Inspection System:

The four-point inspection technique is one of the most used inspection methods in the textile sector. Defects are categorized by this system according to their position and severity inside the cloth. A four-point grading system is used to classify defects; grade one denotes minor problems, while grade four denotes serious flaws that make the fabric unsuitable for further processing. Manufacturers can effectively classify flaws and make well-informed decisions regarding fabric acceptability by utilizing the four-point inspection system.

Understanding Grey Fabric Inspection

Grey fabric, as it emerges from the weaving process, often contains various imperfections that can affect its appearance and durability. These imperfections may include yarn irregularities, weaving defects, stains, or even foreign particles embedded within the fabric structure. Effective inspection is crucial not only for identifying these issues but also for determining the corrective measures required to rectify or minimize them.

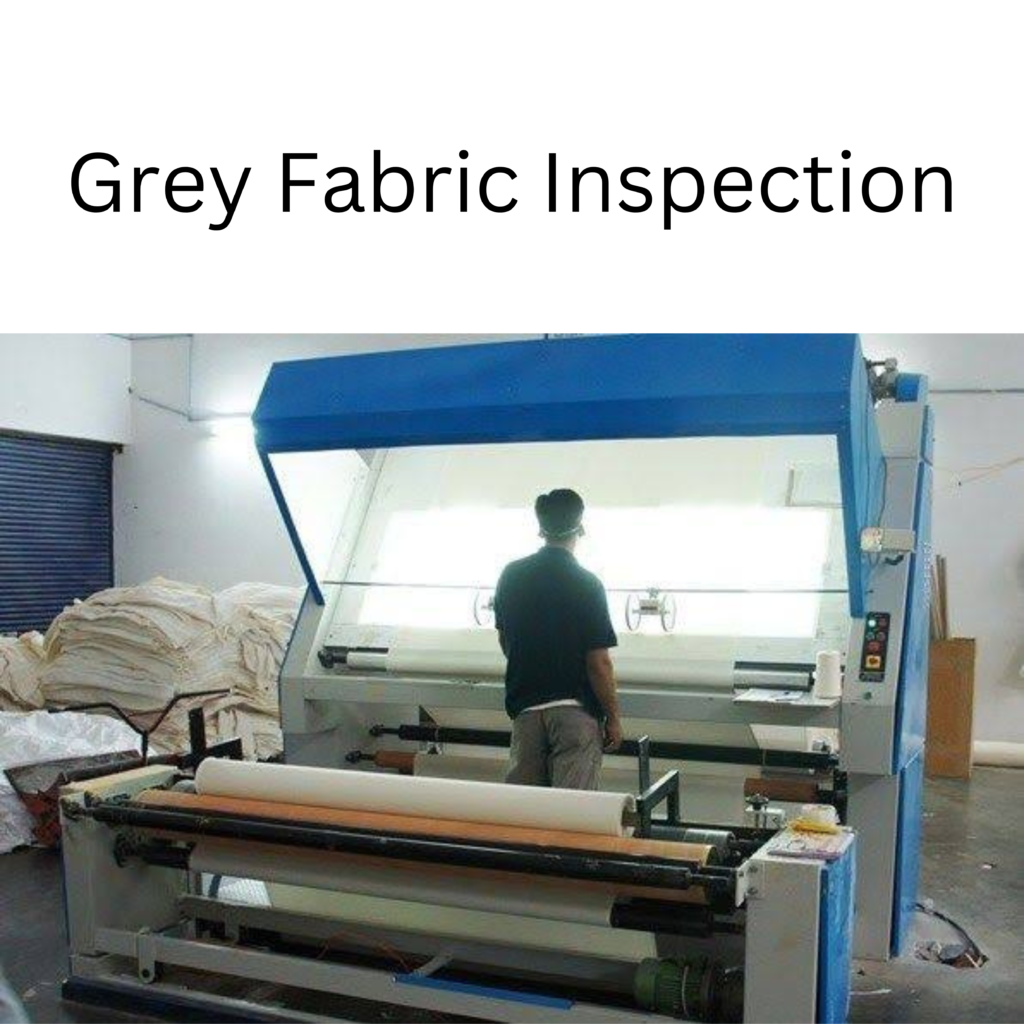

Types of Grey Fabric Inspection Machines

Manual Inspection Tables

Traditional inspection often involves manually spreading fabric over illuminated tables where inspectors visually scrutinize the fabric for defects under controlled lighting conditions.

Automated Inspection Systems

Automated systems utilize advanced sensors and imaging technologies to inspect fabrics continuously as they move through the machine. These systems can detect defects based on predefined criteria and sort fabrics accordingly.

Combination Systems

Some machines combine manual and automated features, allowing for flexibility in inspection processes based on specific fabric types or production requirements.

Problems Occur During Grey Inspection:

Despite the meticulous nature of grey fabric inspection, several challenges may arise during the process. These challenges include:

Common Defects: Typical defects found during grey fabric inspection include weaving irregularities, stains, holes, and misprints, each requiring careful assessment and documentation.

Questions and Answers

- What is grey fabric inspection? Grey fabric inspection involves examining unfinished fabrics for defects before further processing.

Grey Fabric inspection helps understand quality in terms of color, density, weight, printing, measurement, and other quality criteria prior to garment production. - Why is grey fabric inspection important? It ensures quality, reduces costs, and enhances customer satisfaction by preventing defective fabrics from progressing in production.

- What are the types of grey fabric inspection machines? Manual inspection tables, automated inspection systems, and combination systems.

- How do automated inspection systems work? They use cameras and sensors to detect defects in real-time as fabric moves through the machine.

- What are the consequences of improper inspection? It can lead to defective products, increased costs, and compliance issues.

- How has technology influenced grey fabric inspection? Technology advancements have improved accuracy, efficiency, and integration with manufacturing processes.

- What are the challenges in grey fabric inspection? Complex fabric structures, integration issues with ERP systems, and the cost of technology adoption are key challenges.

- What are the emerging trends in grey fabric inspection? AI integration, IoT connectivity, sustainability initiatives, remote monitoring, and customization are emerging trends.

- How can manufacturers optimize grey fabric inspection processes? By investing in advanced technology, training operators, and implementing proactive maintenance practices.

- What is the future outlook for grey fabric inspection? Continued innovation is expected to enhance quality control, operational efficiency, and sustainability in textile manufacturing.

- What is Desizing in Textile Processing: “Desizing” in textiles refers to the process of removing sizing material (starch). It can be done using various chemical agents